Pottery wheels and Kilns - Sales, advice and repairs

Darren McGinn is a recgonised agent for Venco pottery wheels, offering sales, advice, service and repairs.

The go-to entry level model potter's wheel, suitable for beginners to proficient potters.

One of the hardest wearing wheels available – our wheel of choice and that of many institutions and pottery schools.

The Direct Drive, as the name implies uses no belts or gears – the motor is directly coupled to the wheel head.

Contact us for order in requests

NEW LOOK DIRECT DRIVE RANGE

GO,GLIDE & FLOW

THE VENCO RANGE OF DIRECT DRIVE WHEELS HAS EXPANDED.

THE DIRECT DRIVE GO:

BRINGS GLIDE PERFORMANCE IN A BENCH TOP FORM

THE DIRECT DRIVE:

GLIDE IS A HIGH QUALITY MACHINE AT AN AFFORDABLE PRICE

THE DIRECT DRIVE FLOW:

IS A HIGH PERFORMANCE MACHINE FOR THE SERIOUS POTTER.

Kiln & Wheel service & repairs | Studio Set up advice & tuition

kiln & wheel | tele-health check up and advice

100% refundable with Dr. Darren the kiln doctor

the phone chat

fully deductible if you go ahead with the service/order

$100 – This will give you a half hour telephone/video consultation – based on information you have provided with your initial enquiry images/make / model/ etc.

After reading the free advice/information below – and you still haven’t gleaned sufficient information to either: Purchase a secondhand kiln and need some advice or you think your kiln is reparable and you're willing to pay to fix it

- go ahead and purchase a ticket for a phone chat and we'll be in touch.

fully deductible fee

If you decide to go ahead with repair /service – $100 will be deducted from the end cost of the service/ repair invoice.

If you wish to enquire re wheel service ( Venco #3 only ), kiln firing education or studio set up – same applies.

pricing

- call out/ travel fees apply – contact us for local, metro Melbourne and regional quotes

- reasonable, honest and competetive rates

- also specializing in school and institution kiln servicing and repairs

tell us the problem

Get value for your 30 minute phone chat - a few pictures speak a thousand words

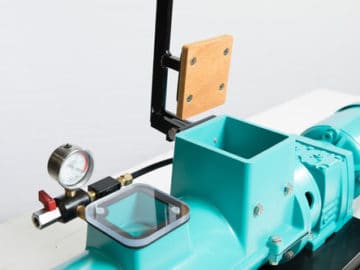

Who plugged the waste outlet?

Plugged waste outlet : Very neat and tidy - no bucket - but don't do this - it will kill the wheel

Buyer beware of purchasing 2nd hand potter's wheels....check the waste outlet hasn't deliberately been blocked.

Just a wee warning - we've been getting a number of enquiries that there's a burning smell emanating and the wheel is sounding clunky....we've literally turned the wheel on on arrival and its smoked out the studio.

People are silly - Never .. ever, ever - ever plug the waste outlet. Its integral to the design and is crucial to allowing the waste water flow out, otherwise the waste has nowhere to go and it will ultimately accumulate internally and burn out your engine... its repairable but avoidable.

PRODUCT RECALL OF :

POTTERY WHEELS, PURCHASED BETWEEN MAY 2015 AND JULY 2018 AND WHEELS WHICH HAD A REPLACEMENT MOTOR FITTED BETWEEN THOSE DATES

DIRECT DRIVE AND NO.7

VENCO NO. 3 AND NO. 5

TO IDENTIFY THE WHEELS IN QUESTION;

Unplug the power supply cord and slowly turn the wheel over onto its side. If the motor supply cable is exiting the motor on the large spring side,this wheel will need to be repaired.

Please stop using your wheel.

Contact the Venco agent that the wheel was purchased from or if purchased second hand, please contact us and we can help.

More information can be found at:

https://www.venco.com.au/recall-notices

images Images Images - cant have enough images

- TETLOW GAS & ELECTRIC KILNS ONLY

-

Kiln make and model– kiln capacity - usually identified on a metal tag attached to the kiln.

- Images - long shots, close ups, identify problem areas with macro shots - we're really trying to get an idea of

- brickwork and elements,

- wiring and plugs, burner ports,

- outside kiln casing and the internal kiln condition.

- temperature controllers, kiln identity tag for make /model, Internal door & hinges, plug ( if electric), burners ( if gas), flue opening( if gas), specific problem spots, detail of brickwork/ elements/rust areas.

- Add a note to your order with time and date options that suit you to be contacted for the initial phone chat.